Patent Technology Empowers Efficient Tufting — Tai Hing’s Custom Brush Filament Smoothness Solutions

The Era of High-Speed Tufting: Brush Filament Smoothness Becomes the Key Bottleneck

With the ongoing automation and mechanical upgrades in China’s brush manufacturing industry, many companies are now adopting high-efficiency automatic tufting machines — some capable of tufting at speeds of 5 to 8 holes per second. Such high-speed operations impose extremely strict requirements on the smoothness of brush filaments:

- If the filaments are not smooth enough, the machine may struggle to pick up fibers, leading to jamming, reduced tufting success rates, or even mechanical damage and production delays.

- If the filaments are too slippery, they can easily fall or be under-gripped by the picker, preventing proper fixation and resulting in poor brush quality.

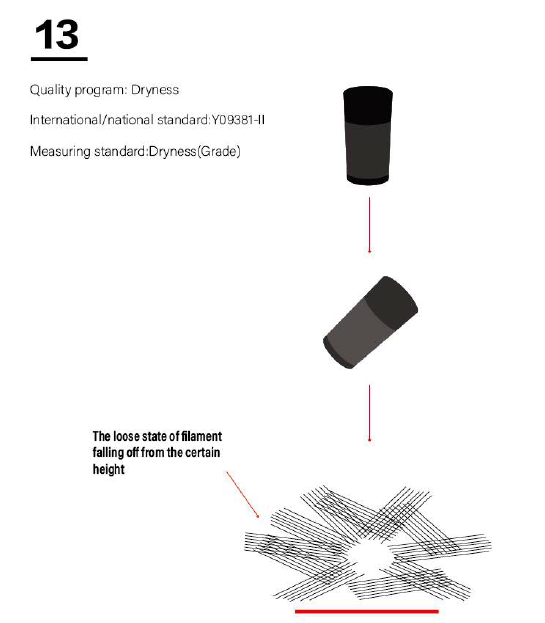

Breakthrough Patent Technology: Measurable and Controllable Smoothness

Tai Hing has developed a patented brush filament smoothness detection technology (Patent No. ZL 2019 2 1188678.1) that precisely tackles the industry-wide challenge of controlling filament smoothness.

Focusing on the customization of ultra-fine filaments below 0.2 mm in diameter, we precisely calibrate and lock in the optimal smoothness range, ensuring consistently smooth fiber pick-up and preventing issues like filament slippage and misalignment at the source.

After pick-up, the filaments remain stable and non-loosening, eliminating the need for the traditional pre-soaking step before tufting — significantly boosting production efficiency.

Our custom filaments feature extremely low tackiness, producing brushes with well-defined, upright bristles — ideal for interdental brushes, mascara brushes, and nail polish brushes. They perfectly match the demands of high-speed tufting machines, providing a stable and reliable core material for automated production processes.

Customized Solutions to Enhance Quality and Efficiency

To meet diverse manufacturing scenarios and equipment models, Tai Hing offers tailored filament smoothness customization services. By combining our patented testing technology with precise formulation adjustments, we help customers completely overcome filament pick-up challenges in high-speed tufting.

The results: significantly improved tufting efficiency, higher product qualification rates, reduced machine wear, and minimized production downtime.

Choose Tai Hing custom brush filaments — supported by patented technology and personalized solutions — to ensure seamless high-speed tufting performance. Empower your brush manufacturing operations to stay ahead in the era of automation and secure a lasting competitive edge.