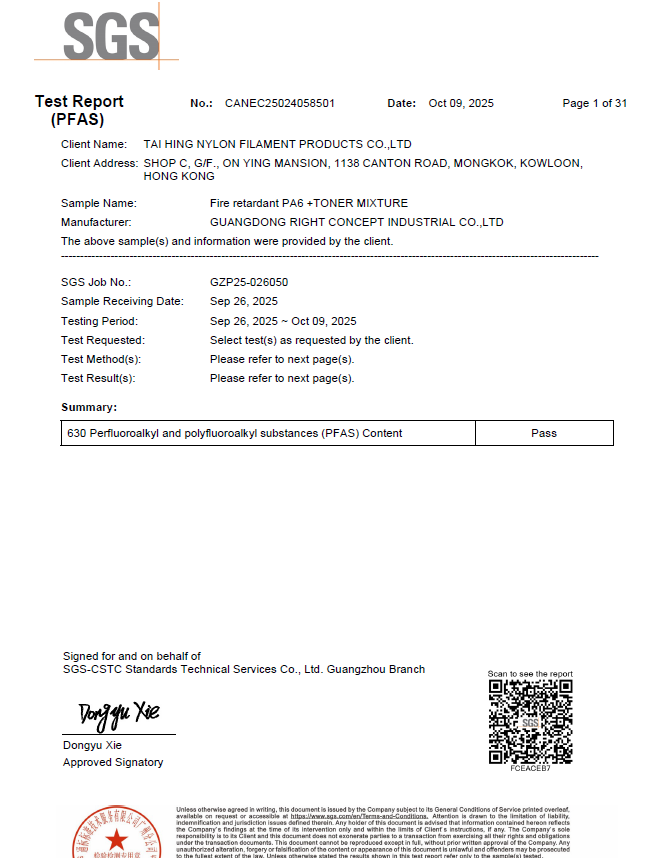

PFAS-Free! Tai Hing FRFil-V0 Flame-Retardant Brush Filament — A Triple Breakthrough in Flame Retardancy, Performance, and Sustainability

Market Trend: Tightened PFAS Regulations Make Fluorine-Free Flame Retardancy a Must

Per- and polyfluoroalkyl substances (PFAS), once widely used in polymer formulations, have come under increasing global scrutiny due to their persistence, bioaccumulation, and potential health risks. These substances can cause long-term contamination to soil and water ecosystems and pose direct threats to human health.

The European Chemicals Agency (ECHA) is actively advancing regulations to bring more than 12,000 PFAS compounds under REACH control. Coupled with the rise of global environmental awareness, PFAS-free has become a key market requirement, driving a sharp increase in demand for fluorine-free materials and products.

Core Innovation: PFAS-Free Formulation with UL94 V0 Flame-Retardant Protection

In response to this trend, Tai Hing independently developed a proprietary non-PFAS flame-retardant technology and launched the FRFil-V0 Flame-Retardant Brush Filament. This innovative product achieves breakthroughs in both heat resistance and flame retardancy — all without the use of PFAS.

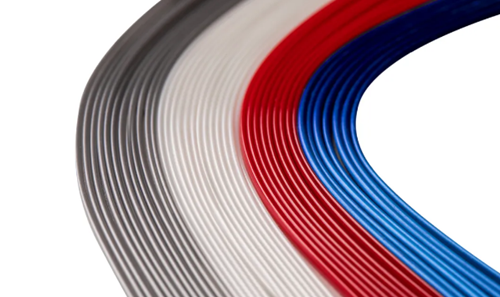

Meeting the UL94 V0 flame retardant standard, FRFil-V0 provides reliable fire protection for a wide range of applications, including transportation, electronic and electrical equipment (e.g., industrial cleaning brushes), furniture, and building materials (e.g., escalator safety strip brushes). It establishes a strong safety barrier across multiple industries.

Balanced Performance: Flame Retardancy Meets Practical Functionality

What truly sets FRFil-V0 apart is that enhanced flame retardancy does not compromise its mechanical or processing performance. Through an optimized and efficient flame-retardant system design, Tai Hing ensures that the product maintains excellent chemical resistance, rigid yet resilient filament stiffness, high impact strength, and dimensional stability.

This balance ensures that FRFil-V0 performs reliably and efficiently in real-world applications, offering both safety and usability.

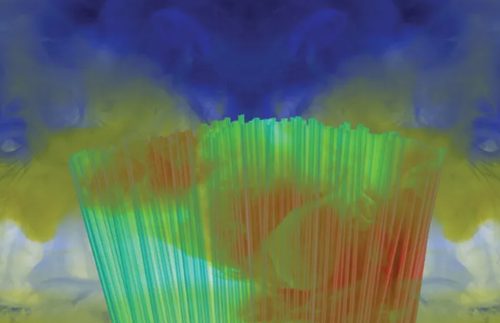

Reliable Results: Inherent Flame-Retardant Technology with Lasting Stability

Consistency and durability in flame performance are among the key advantages of FRFil-V0. The filament is made from UL94 V0-grade raw materials, where the flame-retardant rating climbs progressively from V2 → V1 → V0. It strictly meets the “two 10-second burn tests with flame extinguished within 30 seconds and no flaming drips” criterion of the V0 standard.

Unlike conventional plastic filaments coated with surface flame-retardant agents, FRFil-V0 achieves inherent flame retardancy by integrating special flame-retardant elements directly into its raw material. This structure ensures long-lasting and stable performance, eliminating the risk of flame-retardant degradation over time.

Building a Safe, Sustainable Future Together

From regulatory compliance and performance advancement to environmental responsibility and safety assurance, Tai Hing FRFil-V0 Flame-Retardant Brush Filament stands out with four core advantages — PFAS-Free, High Flame Retardancy, Strong Performance, and Recyclability.

Whether you’re adapting to strict international standards or pioneering sustainable production, Tai Hing offers customized solutions to empower your innovation goals.

We invite partners across industries to collaborate with us — to drive material innovation, accelerate sustainable transformation, and build a safer, greener, and more efficient future together.

For more information or partnership inquiries, please feel free to contact us anytime!

Email: marketing2@taihingnylon.com