GrindFil Abrasive Filaments for Wood Sanding: Parameter Selection and Efficient Application Solutions

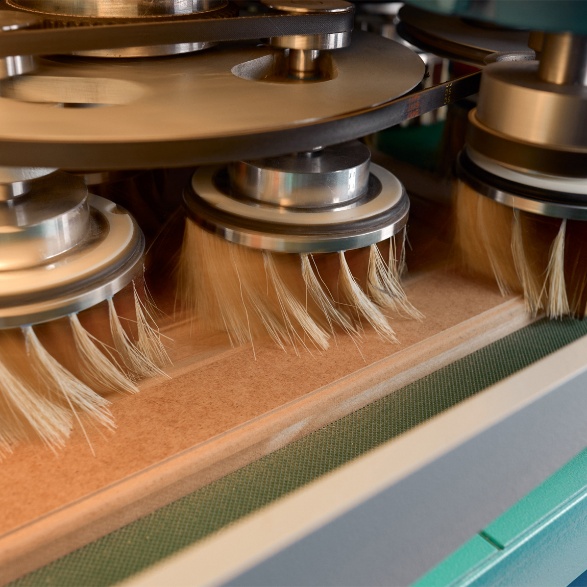

Wood achieves its exquisite finish through rough sanding, fine trimming, and polishing, where abrasive filaments are the core enabler. Tai Hing GrindFil™ Abrasive Filaments are specialized brush filaments made from high-quality nylon (PA612/PA66/PA610/PA6) infused with 15-30% high-purity SiC/AO abrasive grains. With uniform particle dispersion, they offer versatile adaptability, durability, and diverse specs for efficient wood sanding.

Core Selection Principle: Match Filaments to Wood Hardness

Proper matching of filament parameters to wood hardness ensures efficiency and quality, avoiding over-cutting or uneven sanding. Below are tailored solutions for common wood types:

1. Softwood Application Solution (Pine, Fir, Poplar, etc.)

Core Parameters: Aluminum oxide (AO) abrasive, 100-150 mesh (medium grit), 0.3-0.5mm diameter, 15-20% abrasive content.

Rationale: Softwoods are characterized by loose textures and flexible fibers. Aluminum oxide abrasives offer high toughness and gentle cutting action, effectively preventing surface fuzzing and fiber tearing caused by over-cutting. Medium grit sizes directly achieve surface leveling, reducing redundant subsequent fine sanding processes.

Core Benefits: The 0.3-0.5mm fine filament diameter adapts to the deformable nature of softwoods, ensuring uniform sanding. An abrasive content of 15-20% meets deburring requirements while avoiding damage to wood grain caused by excessive abrasives.

2. Hardwood Application Solution (Mahogany, Oak, Cherry, etc.)

Core Parameter Selection:

- Abrasive material prefers silicon carbide (SiC) or high-density aluminum oxide;

- Grit size progresses in a stepped manner: 80-100 mesh (coarse grit) → 180-220 mesh (fine grit) → 320-400 mesh (polishing grit);

- Filament diameter: 0.5-0.8mm; abrasive content: 20-30%.

Rationale: Hardwoods have high density and compact fibers. Silicon carbide abrasives, with higher hardness than aluminum oxide, increase cutting efficiency by over 30%, enabling rapid removal of burrs and tool marks after machining. The stepped grit design achieves process connection of "shaping - finishing - refining," effectively eliminating residual scratches from previous processes.

A filament diameter of 0.5-0.8mm ensures cutting rigidity, while the high abrasive content (20-30%) enhances wear resistance, adapting to the long-term sanding requirements of hardwoods.

Core Benefits:

- Sanding efficiency is increased by 50% compared to conventional configurations;

- Wood grain clarity is improved by 40%; the finished surface has uniform gloss.

- The service life of abrasive filaments is extended by more than 50%, reducing equipment brush replacement frequency and downtime costs.

General Principles for Key Parameters

Grit Size Selection: Follow the "coarse to fine" progressive logic. The final polishing grit size should not be less than 220 mesh to meet the surface roughness requirements of subsequent processes such as painting, waxing, and veneering.

Filament Diameter Control Standard: Avoid using filaments with a diameter exceeding 1.0mm. Test data shows that the unit time wear of 1.4mm diameter abrasive filaments is twice that of 1.2mm, and it will reduce filament density, leading to decreased sanding uniformity.

Abrasive Content Threshold: The maximum abrasive content should not exceed 30%. Excessive abrasives will increase filament brittleness, reduce the bending recovery rate by 15-20%, and easily cause filament breakage, affecting sanding continuity.

GrindFil™ Abrasive Filaments, with precise parameter matching and stable performance, have become the professional choice in the wood sanding field. They transform subtle technical advantages into tangible texture and precision on wooden finished products.

For more abrasive filament product details, please feel free to contact: marketing2@taihingnylon.com