Ceramic Fiber — Partnering for the Next Generation of High Performance Polishing and Deburring Materials

In precision manufacturing, efficient, accurate surface finishing is non-negotiable for upholding consistent product quality.

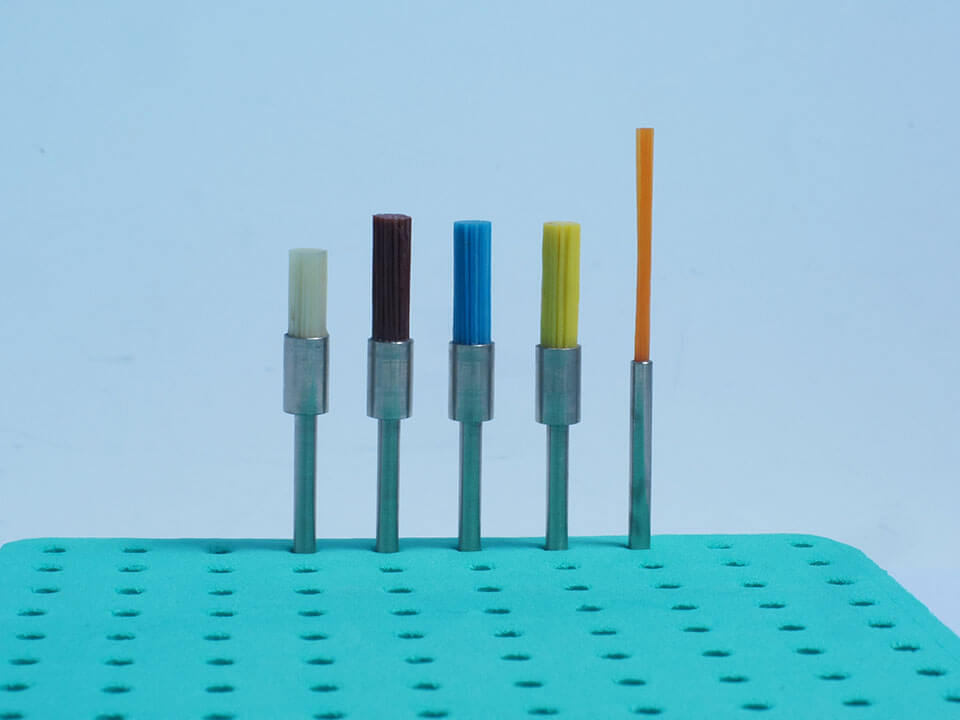

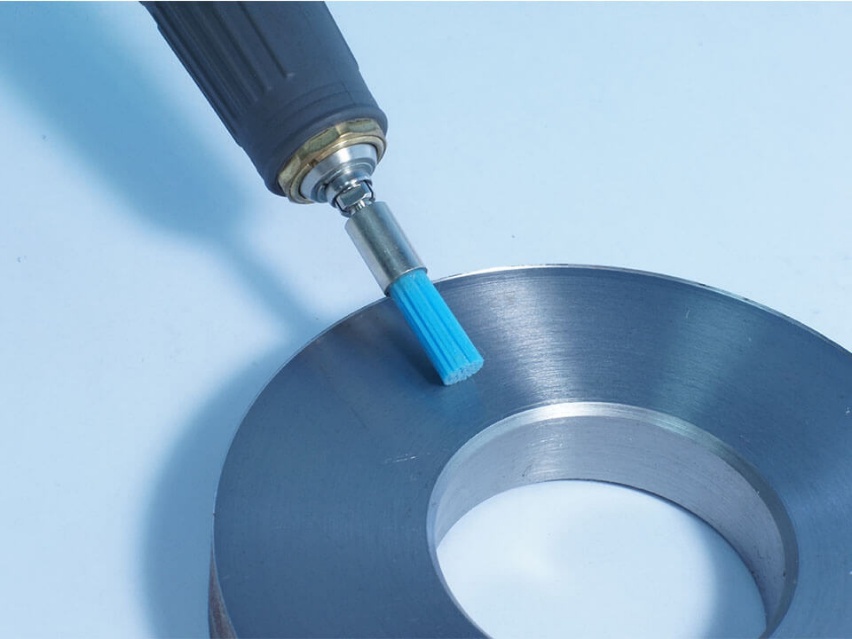

Leveraging Tai Hing’s 40 years of expertise in technical filaments, we have developed a new ceramic fiber line engineered exclusively for automated deburring and polishing applications. Designed to integrate seamlessly with CNC machining centers, lathes, and robotic systems, these fibers deliver reliable, repeatable results when used in commercial ceramic fiber brushes and lathe tools — ideal for high-volume automated production environments.

Core Product Advantages of Ceramic Fiber

-

Exceptional, Consistent Cutting Power

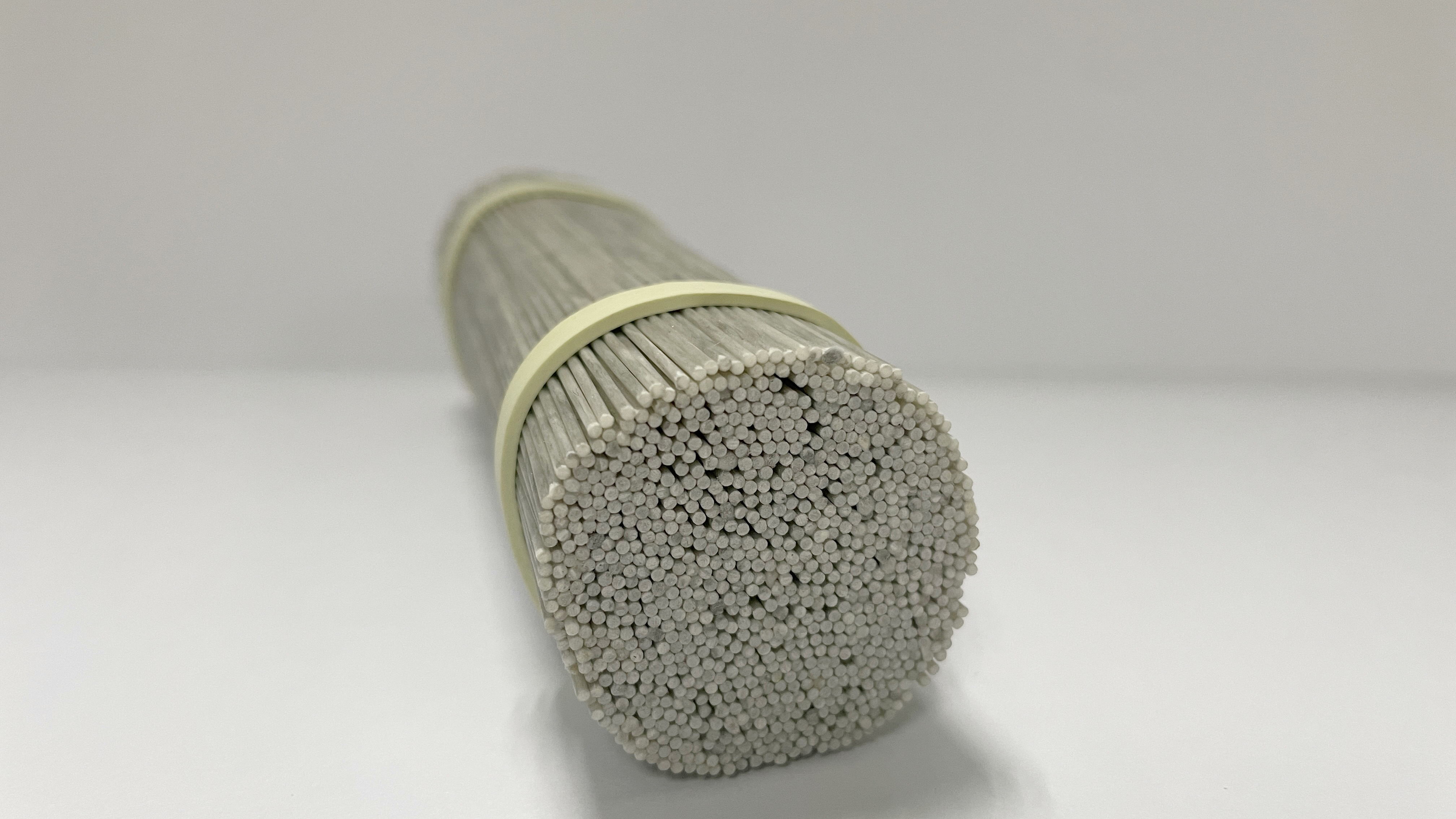

High ceramic content gives these fibers up to 60 times the cutting efficiency of nylon brushes, with stable performance maintained even during extended use. Each filament (5–25 μm in diameter) features thousands of micro-abrasive edges that work simultaneously, delivering steady, controlled cutting action with virtually no performance degradation.

-

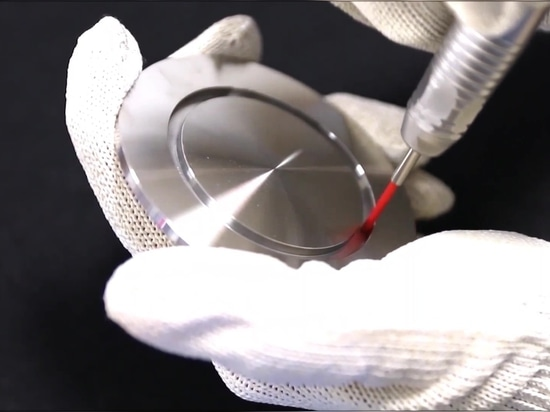

Precision Surface Finishing Without Compromise

Ceramic fibers retain their shape and stiffness throughout operation, eliminating the risk of workpiece surface deformation or damage. They effectively remove burrs and machining marks, improving surface roughness without creating secondary burrs — making them perfect for thread deburring and internal surface finishing of complex components.

-

Broad Material Versatility

These fibers perform equally well on both metals and engineering polymers, including aluminum, stainless steel, carbon steel, PPS, and resin. They streamline surface finishing across diverse workpieces — from mobile device housings and 3C components to precision mechanical parts — ensuring outstanding uniformity, shortening process times, and reducing reliance on manual labor.

-

Self-Sharpening Durability for Long-Term Reliability

The fiber structure self-renews during use, continuously exposing fresh cutting edges for prolonged, consistent performance. Unlike conventional filaments, ceramic fibers maintain their structural integrity run after run, guaranteeing stable, predictable finishing results every time.

Driving the Future of Precision Finishing

Tai Hing’s ceramic fiber technology directly addresses the core pain points of industrial polishing and deburring: boosting throughput, ensuring consistent performance, and delivering superior surface quality.

We invite industry partners to co-develop next-generation polishing materials tailored to your specific machining requirements. Our R&D and application teams provide end-to-end project support — from material formula optimization to full product integration guidance.

Let’s collaborate to deliver more efficient, precise, and sustainable finishing solutions to advanced manufacturing worldwide.

Email:marketing2@taihingnylon.com

Wechat/whatsapp: +86 1882308 1172