Concrete Mixer Truck Tank Cleaning Challenges? Tai Hing Nylon’s Brush Filaments Safeguard Efficient Operations

For concrete mixer trucks, cleaning and maintaining the tank is a core step to ensure their long-term, efficient operation. However, in practical work, residual concrete lumps inside the tank often become a tough issue—it not only affects the quality of materials for the next mixing, but also continuously wears down the tank, significantly shortening the vehicle's service life.

Tai Hing Nylon's brush filaments for concrete mixer truck tanks, made from high-quality materials such as PP, nylon and PET, boast high wear resistance, excellent chemical stability and strong resilience. They have become the ideal choice for various industries looking to improve the cleaning quality of concrete mixer truck tanks. Even under complex working conditions, these filaments perform stably, putting an end to the trouble of residual materials in the tank once and for all.

Core Performance of Brush Filaments: Providing Solid Support for Efficient Cleaning

1. Durable and Wear-Resistant, Reducing Replacement Costs

PP, nylon, and PET, as raw materials for brush filaments, can be called the "perfect materials" for tank cleaning. The internal environment of concrete mixer truck tanks is complex, and the residual concrete has high hardness. Ordinary brush filaments are prone to wear and breakage during repeated friction, resulting in a significant reduction in cleaning efficiency.

Thanks to their robust molecular structure, Tai Hing Nylon's brush filaments maintain their integrity even during high-intensity cleaning operations. This effectively reduces the need for frequent brush replacements due to filament damage, leading to significant long-term savings in equipment maintenance costs.

2. Excellent chemical resistance for long-term cleaning power

The chemicals in concrete are mostly alkaline, and their prolonged adherence to brush filaments can cause corrosion, gradually diminishing the filaments' cleaning ability. Tai Hing Nylon's brush filaments exhibit exceptional chemical stability against concrete, alkaline substances, and various detergents. Even with long-term exposure to concrete residues, their performance remains uncompromised, consistently delivering deep tank cleaning and ensuring no contamination of mixed materials.

3. Optimal hardness for both cleaning and protection

To thoroughly remove residual materials when cleaning the tank, brush filaments need to fit tightly against the tank surface. Tai Hing Nylon's brush filaments strike the perfect balance in hardness: they provide sufficient friction to easily tackle stubborn stains, while creating a moderate buffer upon contact with the tank to avoid scratching its paint. This truly achieves the dual effect of thorough cleaning and careful protection.

4. Paint-safe and long-lasting, balancing quality and cost-effectiveness

Ordinary brush filaments are either too hard, which easily scratches the tank's paint and accelerates rusting; or too soft, which wears out quickly and requires frequent replacement—adding costs and disrupting work efficiency. Through precise material proportioning and process optimization, Tai Hing Nylon's brush filaments achieve the dual advantages of "paint safety" and "long service life." They gently protect the tank surface during cleaning, eliminating paint damage caused by cleaning. Meanwhile, their fatigue resistance far exceeds that of ordinary filaments: after a single replacement, they can withstand longer periods of high-frequency operation, reducing downtime for replacements and ensuring continuous, efficient equipment performance.

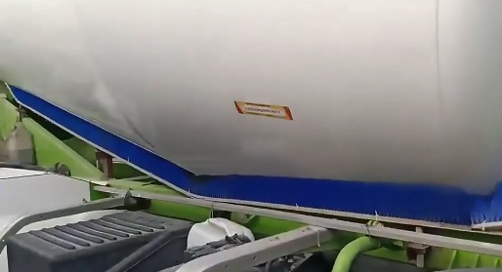

Application in Concrete Mixer Trucks: A Testament to High-Efficiency Cleaning Performance

In the daily operation of concrete mixer trucks, tank cleaning is a critical factor affecting work efficiency and vehicle lifespan. Tai Hing Nylon's brush filaments are specifically designed for cleaning mixer truck tanks, easily handling various complex conditions inside the tank.

Whether it’s the curved inner surfaces, corner gaps, or residual hard concrete lumps, Tai Hing Nylon's brush filaments can tightly adhere to these areas for deep cleaning, thoroughly removing residual materials. This not only prevents residual concrete from affecting the quality of materials for the next mixing but also reduces tank wear, extending the service life of the concrete mixer truck.

Additionally, their high cleaning efficiency reduces the workload and time required for manual cleaning, allowing the concrete mixer truck to return to operation more quickly. This boosts overall work efficiency and provides strong support for project progress.

Choosing Tai Hing Nylon's brush filaments for concrete mixer truck tanks means choosing efficiency, durability, and peace of mind. They completely solve the problem of tank residue, keeping your mixer trucks in optimal condition, helping you gain an edge in construction operations and create greater value!

For customers interested in the product, scan the QR code to add Manager Peng on WeChat for consultation and customized solutions.

Email: marketing2@taihingnylon.com