With High Straightness over 95% and Moderate Hardness and Softness, Tai Hing’s Filament for Nail Polish Brush is Outstanding

01. Introduction of Filament for Nail Polish Brush

Because of inadequate quality control, some nail polish brushes bend when they are soaked in the nail polish for a long time in the production process.

In order to solve this difficulty, Tai Hing has decided to organize the professional R&D team to make the manufacturing technique improvement project of filament for nail polish brush. Through grinding, researching and exploring for many times, Tai Hing’s R&D team finally has developed the manufacturing technique improvement project to make filament maintain the straightness over 95% by adding the straightness treatment technology in the production process.

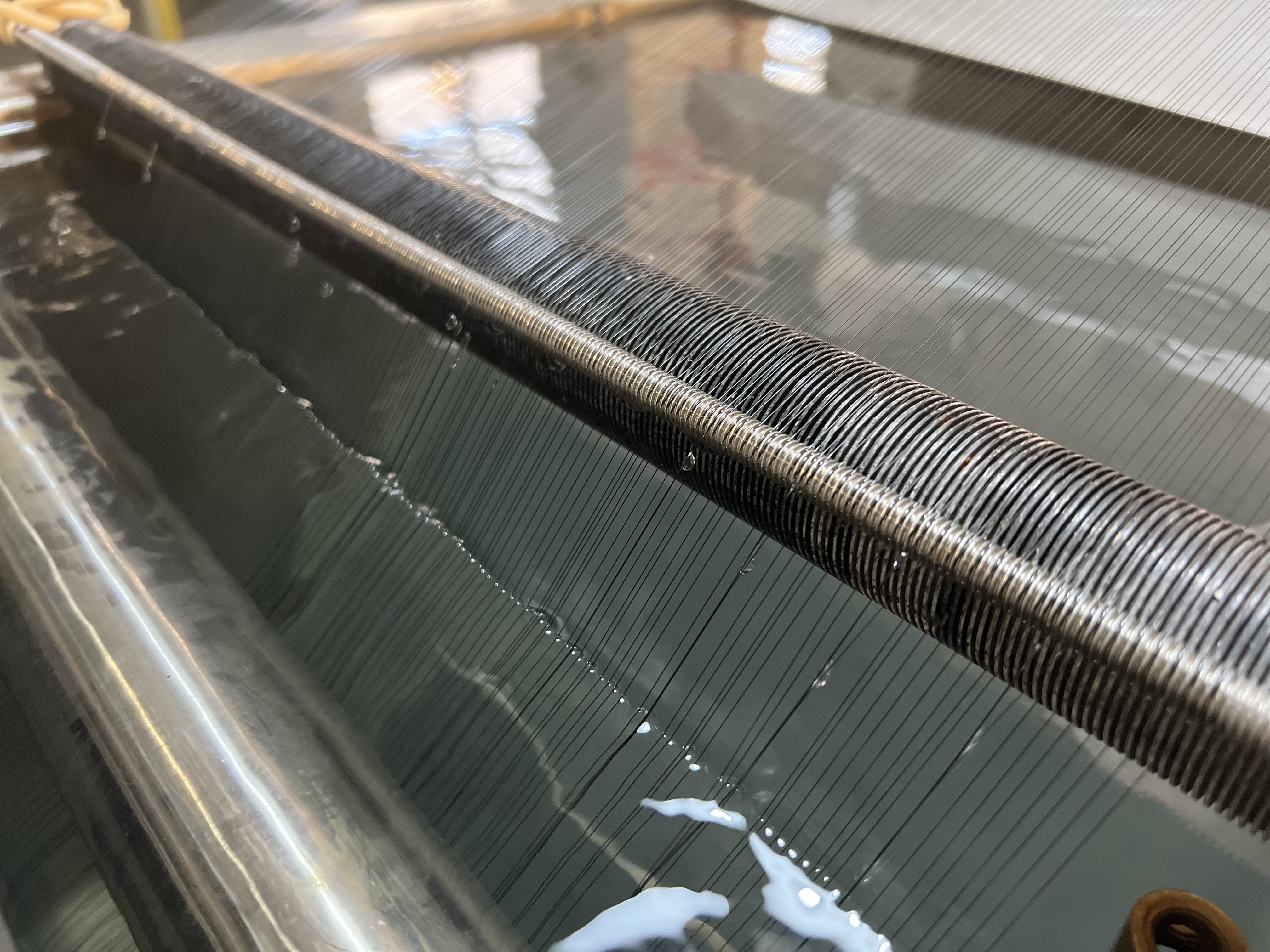

02. Introduction of Manufacturing Technique of Filament for Nail Polish Brush

After the production workers melts the raw material and squeezes it out in the liquid, the high-quality filament for nail polish brush with high stability, low defective rate and effective liquid absorption is produced through the special manufacturing technique of cooling forming, heating and stretching, which manufacturing technique improves the straightness of filament over 95%. The thermal motion of molecules within filament speeds up, which makes the internal stress of filament accumulated in the stretching process release quickly. Such manufacturing technique makes filament straight and the filament do not bend when it is used.

03. Performance Introduction of Filament for Nail Polish Brush

Tai Hing's Filament Has Excellent Characteristics of Straightness and Smoothness

A. Outstanding Tufting Effect

The diameter of best filament for nail polish brush is between 0.05 and 0.1 mm. Adopted Tai Hing’s filament, your brush head is straight and full. The brush head with the same upper and lower width can cover the nail perfectly, which is super convenient and effective to paint nail.

B. Absorbing Liquid Evenly Can Reduce Brush Mark Effectively

The straightness of Tai Hing’s filament for nail polish brush is controlled by the strict quality standard. Each even and smooth filament can improve the liquid absorption evenly and cover the nail smoothly to reduce the brush mark effectively.

04. Straightness Test Method (Boiling Water Immersion Method)

Though many test methods, Tai Hing found that the effect of the boiling water immersion method is close to the nail polish test method’s. The boiling water immersion method is better than nail polish test method because of its environmental characteristics, simple test operation and shorter test time (the time of test result of boiling water immersion is 20 minutes while the time of test result of nail polish is 24 hours) The operation of boiling water immersion test is as below:

1) According to the requirement of CPK data sampling standard, tester needs to prepare more than 35 sample groups and cut the samples from the position 20 meters after the beginning of the spindle because the samples of that position are of more high quality. What’s more, the lesser quantity of filament tows is better for tester to obverse the test effect of each filament in one sample group carefully.

2)First, the tester need to prepare 35 bunches of filament tows with the length of 20mm.

3)At the beginning of test, tester puts 35 bunches of filament tows into the 100℃ boiling water for one minute. After the time, tester takes the samples out of the liquid by the instrument and let them dry by airing.

4)After observation, the curved sample is unqualified. Finally, Tai Hing’s R&D team will test the filament samples through many improved manufacturing technique solutions and choose the best manufacturing technique solution for the nail polish brush filament. Tai Hing will always adhere to the principle of customer-first and aim to help clients to solve theirs difficulties of filament.

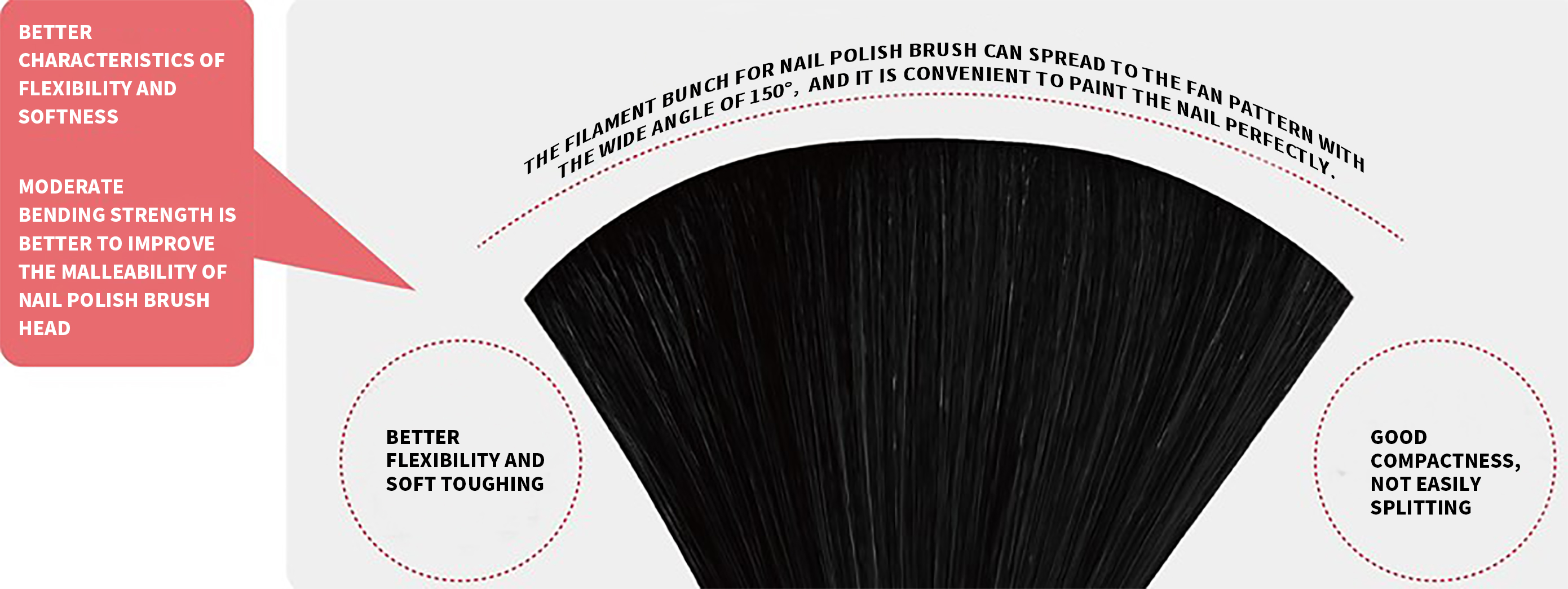

05. Tai Hing’s Filament Has the Characteristics of Moderate Hardness and Softness

With better performance of flexibility and soft toughness, the moderate bending strength of filament is better to improve the malleability of nail polish brush head and its wide angle brush head can cover the nail smoothly. The filament for nail polish brush spreads to the fan pattern with wide angle which matches the nail perfectly during painting the nail. The fan pattern of spread filament increases the painting area and improves the painting effect. The edge of filament for nail polish brush is neat, smooth and straight, which is effective to avoid panting the skin on the edge of the nail.

06. Tai Hing’s Filament Has the Characteristics of High Chemical Stability

Excellent product performance of Tai Hing can avoid filament from fading effectively. The qualified filament for nail polish brush need to soaking in the common medical alcohol and the specific solvents simulated as the nail polish for 168 hours, and finally the tested filament do not fade after soaking in the solvents.

07. Special Surface Treatment Technology

According to the clients’ brush manufacturing machines, Tai Hing can offer customized filament with outstanding characteristics of smoothness to increase tufting efficiency and reach excellent tufting effect. The filament specific surface smoothness treatment technology designed for nail polish brush can reduce the problem of filament dispersing in the brush production process effectively and increase the filament compactness on the brush. Meanwhile, such special surface treatment technology can maintain the surface friction of filament, increase the tension of the whole bunch of filament on the brush and increase the filament firmness, uneasily shedding. Straight and tight brush head is easy to be cut the untidy part of the filament bunch, and it is convenient for brush manufacturers to produce all shapes of brush head, such as flat head and round head and so on.