Tai Hing Anti-Static and Conductive Filament Solutions — Safeguarding Precision Manufacturing and Everyday Quality

In countless industrial and daily scenarios, static electricity is like an invisible troublemaker, causing disruptions and hidden risks. From interfering with electronic devices to triggering hazards in flammable and explosive environments, static issues can’t be ignored.

With 40 years of expertise in industrial monofilament R&D and manufacturing, Tai Hing Nylon Filament Products Co., Ltd. leverages cutting-edge technology to deliver three core product lines—Anti-Static, Conductive, and Long-Term Anti-Static—offering customized static control solutions that protect safety and boost efficiency for customers worldwide.

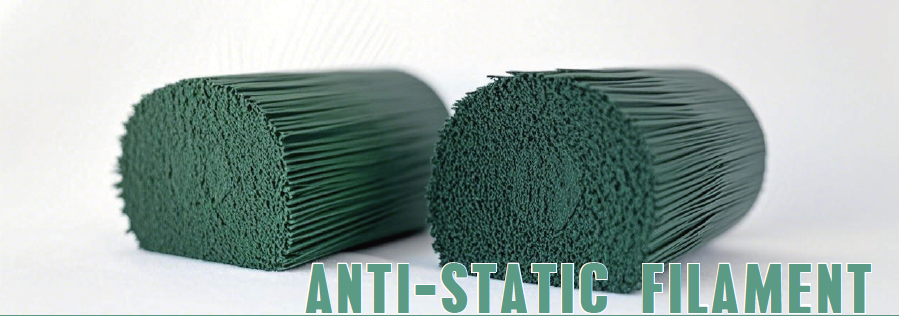

Anti-Static Brush Filaments

(1) Product Overview

Nexfil - AS anti-static filaments are produced by adding anti-static agents into the base resin prior to melt spinning. These agents migrate to the plastic surface, where anti-static molecules bloom to form a hydrophilic layer. By absorbing ambient moisture, the surface resistivity is reduced, delivering long-lasting and stable anti-static performance. Note that effectiveness may be influenced by the agent’s migration time and environmental humidity.

(2) Advantages and Applications

Precise resistivity: Maintains an optimal resistivity in the 10^11–10^12 Ω range—ideal for static dissipation. Primarily used in dust-removal cleaning brushes and escalator safety skirts to ensure industrial safety and passenger protection.

Strong environmental adaptability: Whether in humid or dry conditions, Nexfil - AS retains relatively stable anti-static performance and is suitable for hairbrush applications.

(3) Specifications

Available base materials: PA6 / PA66 / PBT

Color: Customizable

Diameter: 0.10–1.25 mm

Cut length: 25–1220 mm

Filament form: Straight, crimped

Cross-section: Customizable

Conventional anti-static products typically sustain their performance for only 1 month to 6 months. In environments with stringent ESD control requirements—such as electronics manufacturing and flammable/explosive settings—Nexfil - Conductive offers clear advantages. It not only lasts longer but also removes static more effectively. Customers can select according to their needs.

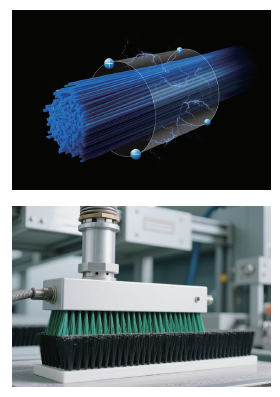

Conductive Brush Filament

(1) Product Overview

Nexfil - Conductive filaments are made by uniformly compounding conductive carbon into the base resin, then extruding at high temperature to form the monofilament. The conductive phase provides mobile electrons. When static charge forms, these electrons conduct it safely to ground through a metal handle connection, rapidly eliminating static.

(2) Advantages and Applications

Outstanding conductivity: Surface resistivity is in the 10^3–10^5 Ω range, delivering long-lasting, stable conductivity for efficient static removal. Widely used in electronics, IC manufacturing, EMI shielding, escalator skirts, door/window sealing dust strips, printers, and more—supporting production safety and equipment reliability.

Mechanical integrity: Excellent conductivity without compromising the inherent mechanical properties of the base materials.

(3) Specifications

Available base materials: PA6 / PBT / PP

Color: Black

Diameter: PA6: 0.20–1.25 mm; PBT: 0.10–1.25 mm; PP: 0.15–1.0 mm

Cut length: 25–1220 mm

Filament form: Straight, crimped

Cross-section: Customizable

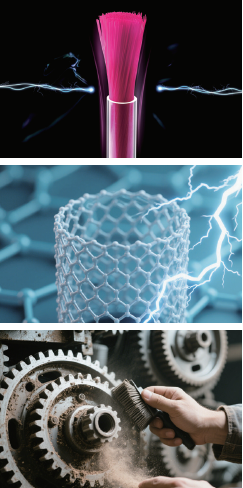

In industries with exceptionally high and humidity-insensitive ESD requirements—such as precision electronics, aerospace, and advanced medical equipment—traditional anti-static filaments often struggle to deliver stable, continuous performance. Nexfil - LTAS Long-Term Anti-Static filaments stand out with unique advantages, providing reliable static protection to prevent issues caused by static electricity and ensuring smooth production and R&D.

Long-Term Anti-Static Brush Filament

(1) Product Overview

Unlike spray-coated or bloom-type anti-static filaments, Nexfil - LTAS forms a stable network structure of functional polymers both within and on the surface of the filament. This structure is humidity-independent, ensuring stable resistivity and non-decaying anti-static performance over time.

(2) Advantages and Applications

High stability: Resistivity remains steady in the 10^6–10^12 Ω range. Whether in humid southern regions, dry northern climates, or environments with frequent humidity swings, it consistently delivers anti-static protection. Ideal for chip fabrication cleanrooms and optical instrument cleaning tools, such as wafer cleaning brushes and in-equipment brushes—effectively preventing ESD damage to chips and optics to improve yield.

Long-lasting performance: Unlike conventional anti-static filaments that degrade over time, the polymer network in Nexfil - LTAS prevents performance decay. Once deployed, it remains effective long term, significantly reducing replacement frequency and cost. Applicable to pharmaceutical production cleaning brushes and anti-static components in filling equipment to ensure product quality and safety.

Excellent compatibility: While maintaining superior anti-static performance, it does not compromise the base material’s mechanical properties. With PA6, PA66, PA610, PA612, or PBT, the filaments retain flexibility, wear resistance, and strength to meet physical performance needs across diverse applications.

(3) Specifications

Available base materials: PA6 / PA66 / PA610 / PA612 / PBT

Color: Customizable

Diameter: 0.15–1.25 mm

Cut length: 25–1220 mm

Filament form: Straight, crimped

Cross-section: Customizable

Tai Hing Nylon Filament Products Co., Ltd. delivers tailored anti-static and conductive filament solutions to protect safety, enhance efficiency, and elevate the quality of precision manufacturing and everyday life.

Should you have any interest in our filament solutions, please do not hesitate to reach out.

📧 Email: marketing2@taihingnylon.com