Ratefil™ PC — Turning Brush-Making Challenges into Opportunities

In brush manufacturing, small problems can quickly become big ones.

Filaments that snap after a few uses, brushes that lose shape in heat or humidity, or precision components scratched by rough filaments—these issues raise costs, invite complaints, and erode trust.

Ratefil™ PC from Tai Hing was created to change that. Built on decades of material science expertise, it delivers durability, consistency, and versatility that help brush makers reduce failures and increase customer satisfaction.

Stronger for Industrial Use

The challenge: Industrial brushes often face high-frequency stress, repeated bending, and harsh chemical exposure. Conventional filaments can break, deform, or crack—leading to frequent replacements and downtime.

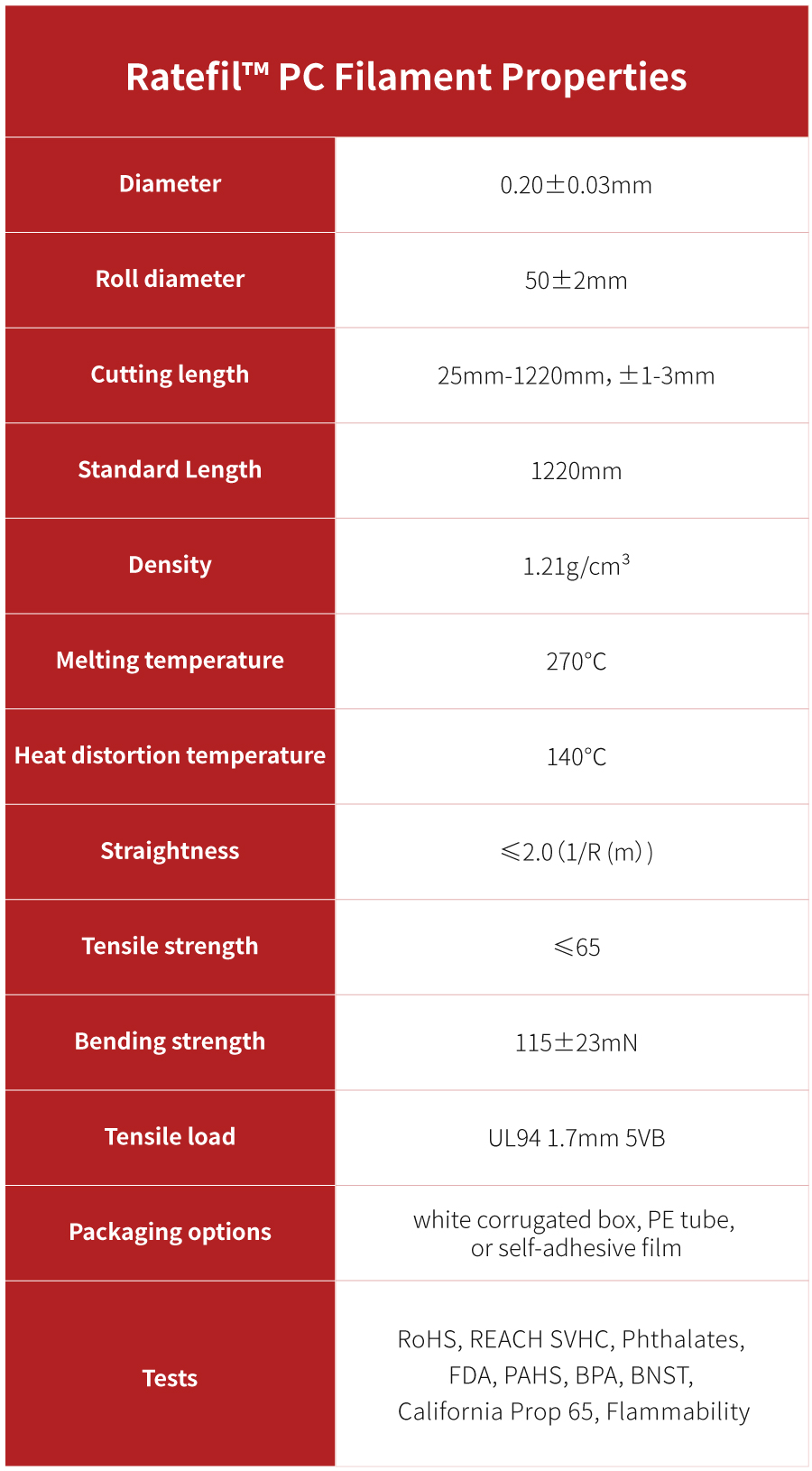

The solution: It delivers a bending strength of 115±23 mN, with impact resistance and hardness far exceeding conventional brush materials. Even under external impacts during polishing or repeated flexing during cleaning, it resists breakage and deformation.

With pull force ≥1.0 N and elongation at break ≤65, it maintains structural stability under high tensile loads. When used in polishing brushes or mechanical sweeping brushes, service life is markedly extended, reducing customer returns and replacements.

It also offers strong resistance to common acids and alkalis, alcohols, gasoline, and other organic solvents. It won’t swell or crack upon contact, ensuring stable performance even for tasks like cleaning reactor vessels in chemical plants or wiping laboratory instruments—no more worries about “chemical corrosion.

Stable in Household Environments

The challenge: In kitchens and bathrooms, brushes are constantly exposed to water and moisture. Many filaments swell, deform, or even grow mold.

The solution: With extremely low moisture absorption, Ratefil™ PC filaments retain their shape and dimension in damp environments. They resist swelling and deformation, while their color stability keeps brushes looking fresh and reliable over time. Consumers enjoy tools that last longer, and you build a stronger reputation.

Safe for Electronics and Precision Work

The challenge: Cleaning sensitive components like circuit boards or chips requires absolute care. Filaments that are uneven, rough, or unstable can scratch surfaces and cause serious damage.

The solution: The filament diameter is precisely controlled at 0.20±0.03 mm, with straightness ≤2.0 (1/R, m). The bristles stay upright without sagging, align evenly, and maintain consistent contact pressure. When cleaning electronic components, they conform accurately to surfaces without leaving scratches from uneven force.

An ultra-smooth surface design reduces friction when touching precision parts. It efficiently removes dust and debris while preventing abrasion of components—whether cleaning smartphone motherboards or handling computer chips—giving customers peace of mind and sparing you from “scratch-claim” headaches.

A Partner You Can Trust

For over 40 years, Tai Hing has focused exclusively on brush filament innovation. From raw material selection to advanced processing, every step is designed to meet the real-world needs of brush makers.

With Ratefil™ PC, you get more than a material—you get a solution to the everyday challenges of your industry. More durable brushes, happier customers, and healthier margins.

Ready to experience the difference? Contact us today for detailed specifications and free samples of Ratefil™ PC.

Email:marketing2@taihingnylon.com