Nano-Material New Star: Tai Hing’s Aerofil™ Ushers in a New Era of High-Efficiency Cleaning

In the fast-evolving field of materials science, aerogel brush filaments—an innovative blend of nanotechnology and functional devices—are reshaping cleaning standards across industries with their disruptive performance.

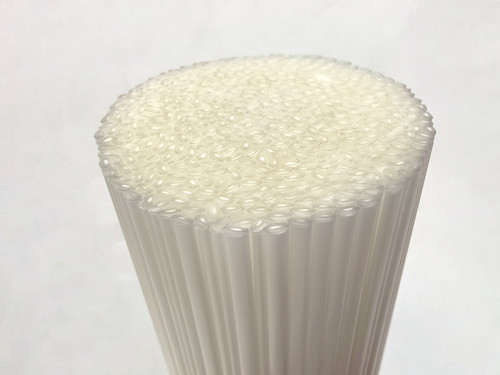

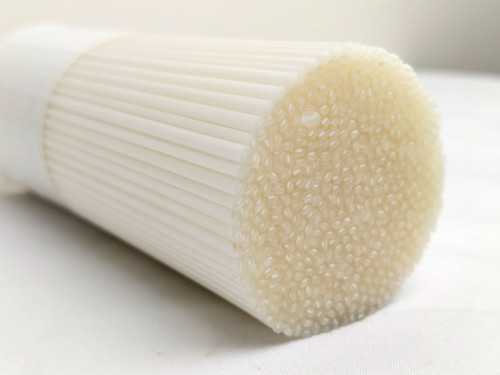

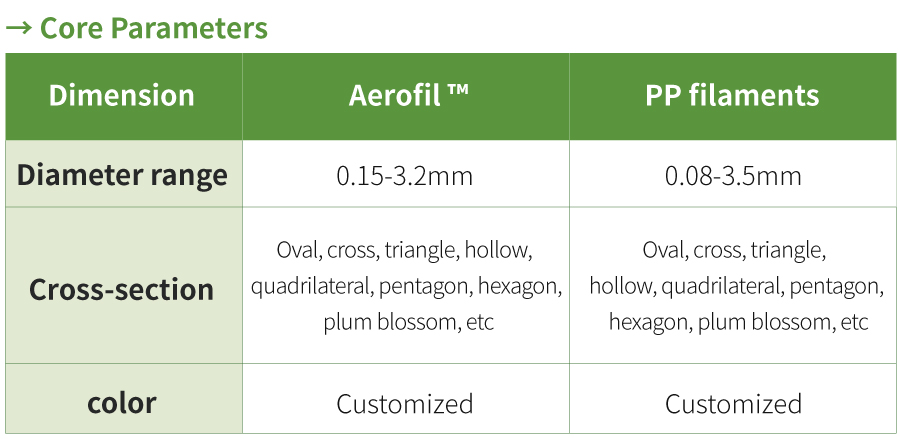

Tai Hing has deepened its R&D in Aerofil™, integrating the nanoporous structure of aerogels with brush filament morphology through cutting-edge technology, unleashing transformative power in high-end manufacturing.

Six Core Technical Advantages Redefining Industry Benchmarks

1. Superior Thermal Insulation

The nanoporous microstructure of Aerofil™ endows it with exceptional adsorption, filtration, and thermal insulation capabilities, demonstrating unparalleled value in environmental filtration and oil contamination treatment.

2. Exceptional Low-Temperature Toughness

Crafted with improved carbon-based technology, Aerofil™ maintains excellent impact resistance at -40°C, resisting breakage even under repeated bending.

3. Outstanding Rebound Performance

With a single-filament bending recovery rate of 147°, Aerofil™ far exceeds PP brush filaments, ensuring rapid reset after cleaning for long-term durability.

4. Optimal Flexibility & Texture

Its low bending strength ensures a soft texture, making it ideal for cleaning precision components like electronic devices and optical lenses.

5. High Chemical Stability

Resistant to acids, alkalis, and organic solvents, Aerofil™ performs stably in complex chemical environments.

6. Long-Lasting Aging & Weather Resistance

The unique porous structure shields against UV rays and moisture, significantly extending service life.

Five Core Application Scenarios Unleashing Diverse Value

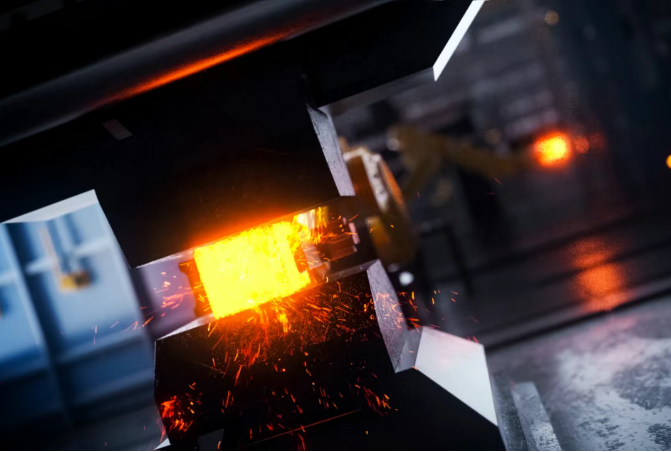

1. High-Temperature Industrial Cleaning

In petrochemical and metallurgical environments exceeding 400°C, Aerofil™ reinforced with ceramic fibers withstands temperatures up to 650°C. Its lightweight design replaces metal brushes, enhancing operational efficiency and safety.

2. Precision Instrument Maintenance

Graphene-infused Aerofil™ eliminates static electricity through its conductive properties. The nanoscale pores prevent surface scratches, enabling damage-free cleaning of semiconductors and optical lenses.

3. Medical & Biotech Equipment

Chitosan/Aerofil™ composites leverage natural antibacterial properties and high specific surface area for efficient sterile cleaning of endoscopes and surgical instruments.

4. Environmental Oil Spill Remediation

Lignocellulose-based Aerofil™ adsorbs oils up to 300 times its own weight while remaining biodegradable, offering a sustainable solution for oil contamination cleanup.

5. Intelligent Cleaning Devices

With an ultra-low density of 0.856kg/m³, Aerofil™ meets the payload requirements of robots and drones. Doped with functional additives, it integrates pressure sensing capabilities to advance smart cleaning technology.

From high-temperature furnaces to precision chips, ecological rescue to smart terminals, Tai Hing’s Aerofil™ continues to expand application frontiers through technological breakthroughs.

In the future, we will persist in innovation, empowering industries with superior products and solutions to co-inaugurate a new era of cleaning technology.

If you are interested in our new filament products, please feel free to contact us.

Email:marketing2@taihingnylon.com

Whatsapp/Wechat:+86 18823081172