How to Accurately Identify the Quality of PEEK Brush Filaments

PEEK brush filaments are widely used in industrial and high-tech fields, and their quality significantly impacts performance. Here are key aspects to consider for quality assessment:

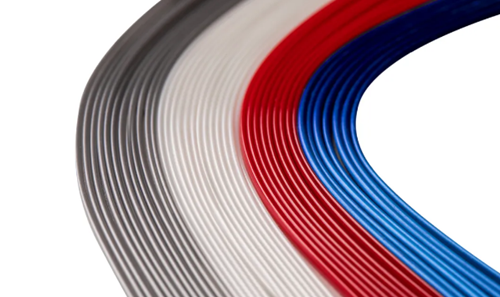

Appearance

High-quality PEEK brush filaments should have a uniform color, be semi-transparent with a natural luster, and be free from impurities or discoloration. The diameter should be consistent, with a regular round cross-section.

Physical Properties

Tensile Strength: Conduct tensile tests to ensure the filaments meet strength standards. High-strength filaments are less likely to break during use.

Wear Resistance: Perform simulated friction tests to assess wear under actual working conditions. Durable filaments should maintain their shape and diameter.

Chemical Resistance

Soak the filaments in common chemical agents to check for dissolution or swelling, indicating their resistance to chemical corrosion.

Thermal Stability

Use thermogravimetric analysis to evaluate thermal stability. Filaments that show minimal weight loss at high temperatures are more reliable.

Brand and Manufacturing Process

Choose products from reputable brands with advanced manufacturing processes for guaranteed quality.

By considering these factors, you can select high-quality brush filaments for your needs!